Centrifugal compressors are among the most popular and efficient types of compressors used in industrial applications. These compressors are used to increase the pressure of a gas or liquid by using centrifugal force to increase its velocity. As a result, the pressure of the fluid increases as it passes through the compressor. If you want to know more about centrifugal compressors you may contact Dynamicrental .

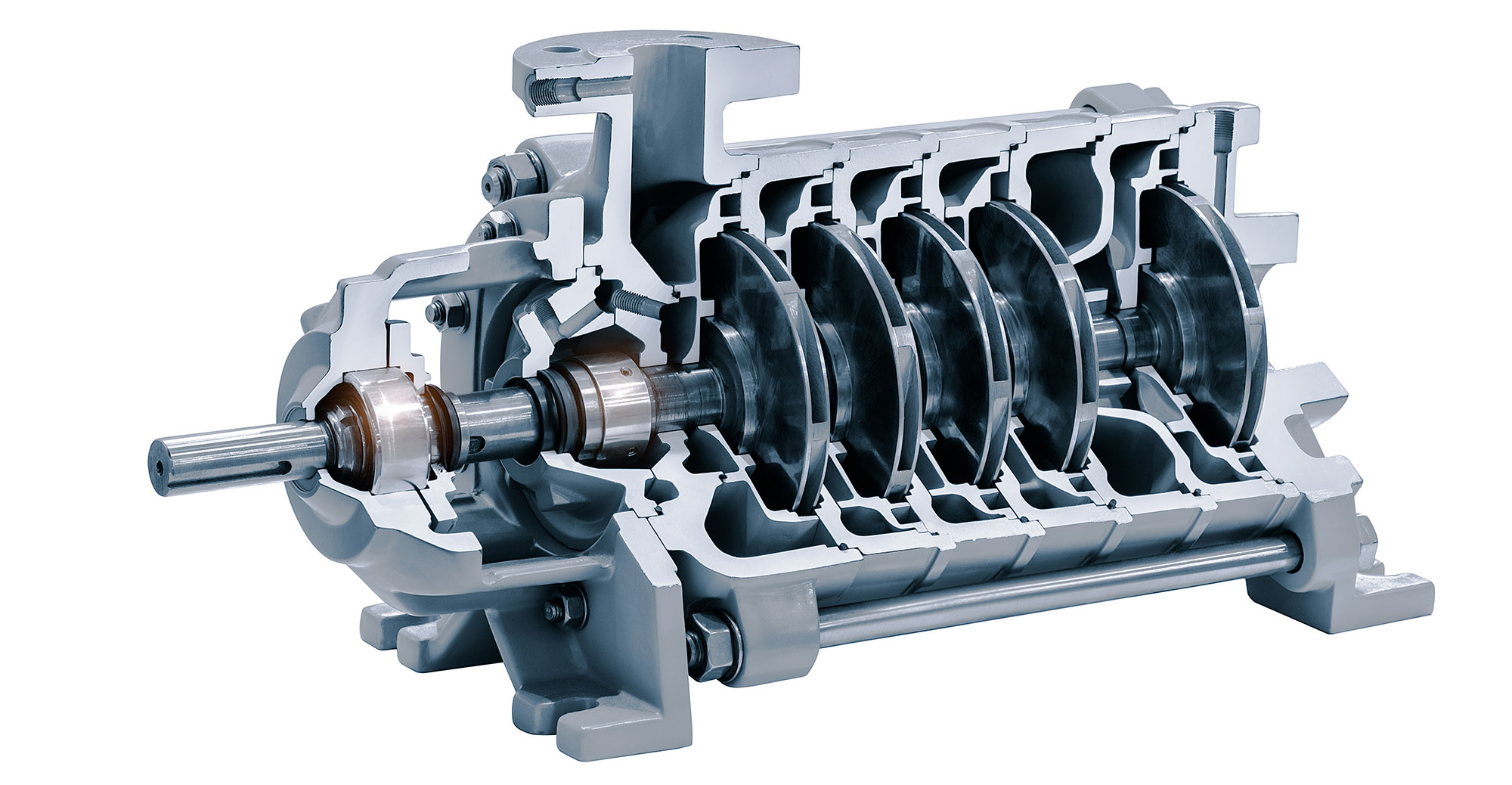

Image Source : Google

Here are some advantages of using centrifugal compressors for industrial applications:

1. High Efficiency: One of the main advantages of compressors is their high efficiency. The compressor is designed to generate a high level of output in a short amount of time. This allows the compressor to operate at a much higher efficiency than other types of compressors.

2. Compact Design: These compressors are typically much smaller in size than other types of compressors. This makes them ideal for applications where space is a concern. The small size also makes them easier to install, maintain, and transport.

3. Low Maintenance: These compressors are relatively easy to maintain. They require minimal maintenance and can last for many years, even with regular use. Furthermore, they are designed to be more reliable than other types of compressors.

4. Noise Reduction: Centrifugal compressors are designed to operate with minimal noise. This is beneficial for industrial applications where noise levels need to be kept to a minimum. The low noise levels make them ideal for use in environments where noise needs to be kept to a minimum.